After working with hundreds of top construction companies, helping deliver 3,000+ projects worth over £35 billion, and engaging with 10,000+ users of our software, we’ve gained a deep understanding of procurement.

On the surface, procurement looks straightforward — subcontractors and materials are orchestrated to arrive on site, on time and on budget. But that’s just the tip of the iceberg.

So what is it most don’t see? The shifting plates below — tender prep, supplier negotiations and sourcing, cost analysis, contract drafting, dispute resolution, tracking, scheduling, and the thousand other things that go into getting those trades to the site and making margin in the process.

With it being so complex, it’s no wonder procurement was highlighted in the UK Government’s Construction 2025 industrial strategy as a key focus area for efficiency and process overhauls.

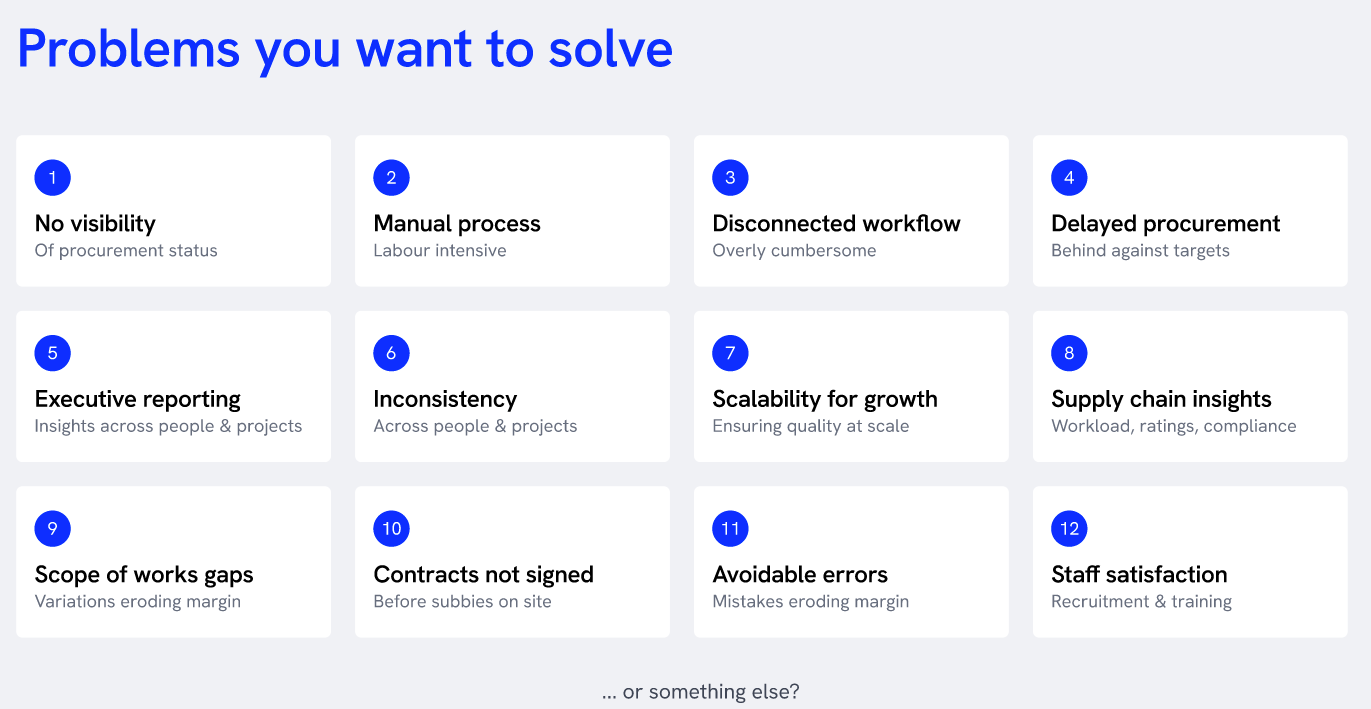

But, knowing that it’s inefficient is only the start. Read on to discover the 12 problems of procurement and how to solve them.

To develop The New Way™ of doing things, you have to identify the problems

with doing them The Old Way™.

So, after thousands of hours speaking with people who work “under the surface”, we’ve managed to boil down the most common challenges felt across the construction industry into what we call The 12 Problems of Procurement.

No visibility over procurement status

Most of the teams we speak to only look at the status of each package in a weekly 1-hour meeting. For those counting, that’s up-to-date visibility 2.5% of the time. Status reporting is then forgotten about until the next meeting, or when someone asks “Where is this package up to” or “Have you got quotes back yet?”.

This amounts to almost zero visibility over procurement status at any given time.

Not having access to this important information leaves the big picture half-painted, making it nearly impossible to assess those packages at risk before something can be done about it. This spins up a vicious cycle where work becomes reactive rather than proactive, and delays become inevitable.

It’s then no wonder why 9 out of 10 construction projects experience cost overruns.

The Old Way:

- You’re never sure where a package is up to unless you pick up the phone

- You can’t trust what’s on Excel or make sense of the hundreds of dates on a schedule

- Nobody can access a clear, real-time view of the big picture

The New Way:

- One single dashboard that updates automatically with the progress of each package

- Helicopter view of packages at risk - nothing falls into the red unnoticed

- Easily see who’s responsible for a package, and which packages are due and when so that resourcing never becomes an issue

Manual processes are labour-intensive

Manual processes play a role in each of the 12 Problems of Procurement. For a main contractor, this can amount to upwards of 40 hours per trade, across an average of 30 trades per project, and 15 projects per year.

According to RICS, there’s been a major shortage of new quantity surveyors entering the profession. Their data show that 30% of the workforce is over the age of 50 and that retirements outnumber new graduates. As the adage goes, it’s understandable why the old habits haven’t quite died off and that processes haven’t changed since the late 1990s.

Emails, phone calls, and spreadsheets still dominate procurement workflows and, though we still love a spreadsheet, the majority of these processes can and should be automated to save time, reduce errors, and increase productivity.

Our free calculator will show you where you’re throwing away money.

The Old Way:

- Deciphering and dissecting email threads take forever

- Surveyors sink time into manually updating Excel sheets, schedules, and calendars

- Packages have to be manually progressed from stage to stage going back and forth

The New Way:

- Leave the phone off the hook — all messages about a package are done in one place

- Manual workflows for things like status updates are completely automated

- Surveyors spend less time doing admin tasks and more time value engineering

Does this look familiar?

It’s never a shock when we present this image on calls and reveal that fewer than 20% of these processes or systems are connected.

This disconnect in your workflows leads to wasted time as teams struggle with switching tools and losing track of their work.

The Old Way:

- There’s never just one doc or spreadsheet for a package and they’re all over the place

- Systems don’t talk to each other so you have to move files and data around

- Teams develop hacky, manual workarounds that are inefficient

The New Way:

- Files and data from other systems are pulled into ProcurePro to automate workflows

- All steps in procurement, from tendering to contract signing, are connected

- Integrate the tools that you’re using every day into a single platform

Delayed procurement puts projects behind

In construction, time isn’t just money. It’s reputation….

But it is very much also money.

KPMG’s 2015 study found that, over a three-year period, only 25% of construction projects were completed within 10% of their deadlines, and only 31% came within 10% of budget.

Given that procurement takes place early in a project life cycle, it can feel like a house of cards. For example, you might be able to shuffle the deck a little on design and delivery programmes, but that requires a high level of coordination. One or two missed deadlines can send that house tumbling down.

The Old Way:

- Delays are the norm, rather than the exception

- Procurement timelines slip due to late starts, bad planning, and unforeseen hurdles

- A few slip-ups in communication can push packages into the red

The New Way:

- Get flagged when packages are at risk

- Timelines are easy to follow from a single, visual dashboard

- Procurement milestones and lead times can be baked into your procurement schedule

Reporting lacks actionable insights for all levels

Producing reports that show actionable insights with data from multiple, disconnected sources is tricky business — especially for a busy QS reporting to a commercial manager or project director.

For many QSs we’ve spoken to, reports are often done for the sake of it and proper analysis is an afterthought. Reports are out of date the minute they’re produced and because they don’t always contain relevant data for everyone, are shallow on actionable insights.

One good example is highlighting opportunities to barter for a better offer across a few projects with the same subcontractor (or to ditch an underperforming one). With disconnected communications, projects, and schedules, potential margin (and risk) gets buried in the data and gut instinct drives decision-making.

The Old Way:

- QSs have no time to produce insightful reports for execs to act upon

- Disconnected systems make reporting a tedious and rushed process

- Reports are out of date the minute they’re produced

The New Way:

- Reports are automatically updated, pulling data from all connected projects

- Real-time reporting means catching risks and opportunities when it matters most

- Different roles have access to different levels of reporting based on immediate needs

Everyone does things differently

Regardless of what salespeople might say, adopting a new technology isn’t the answer to everything…but it is unequivocally the answer to this problem.

Two people trained the same way and working on the same projects will find different ways to reach a solution. With limited control, leadership will try and instil the second-hand processes from whichever the favoured office is (usually that's the “London way” of doing things).

Expand that to multiple teams, roles, and departments and you end up with an inefficient, confused team. That’s where using the same system, with the same guardrails, creates real change.

The Old Way:

- Teams pick up different workflows and bad habits from project to project

- Creating standard procedures is impossible with so many tools in the mix

- Bringing in or working with another QS means adapting to their way of working

The New Way:

- Company-wide templates and workflows create consistency and repeatability

- Standardisation of processes means timelines are clear and understandable

- High standards can be attained no matter who is working on the project

Align your procurement with our FREE (for now) Digital Strategy Workshop

Quality drops as volume increases

In short: as teams and projects multiply, so too do the problems of managing procurement. This is partly due to the problem of trying to scale non-standardised processes to growing teams but is also a problem when workloads increase.

An example we’ve come across is one regional operative who didn’t have the budget to increase headcount, so reallocated a QS from another region. That QS then joined the project team playing catchup. Time was wasted bringing them up to speed and the packages (that were already at risk) missed key milestones and were ultimately delayed.

Having scalable, standardised practices in place on a single procurement platform ensures consistent quality as headcount grows.

The Old Way:

- Taking on more projects requires more staff

- Managing quality and consistency across a larger portfolio of projects

The New Way:

- Automation means teams can take on more projects without it being more work

- Everything in one platform makes cross-team collaboration simple

- Procurement becomes systematic and quality becomes consistent

A lack of supply chain insights

Depending on the sector, large contractors typically work with thousands of suppliers, subbies, and partners. At this scale, practising due diligence in compliance checks, workload assessments, and performance ratings is a monumental task. There is risk out there, but where is it and how much will it cost you?

To add to it, supply chains are constantly being rattled, and a broken link in one package can make all the difference to a project.

The Old Way:

- Supplier compliance, ratings, or capacity to deliver is overlooked

- Communications with subbies/suppliers are scattered and data is buried

- Risk isn’t identified until it’s too late

The New Way:

- Compliance checks, vendor ratings, and communications are stored together

- Supply chain risk is highlighted early on in the procurement process

- Automated workflows for all those boring vendor management tasks

Scope-of-works gaps

2024 construction company profits make for a dismal read.

Based on our research, a contractor will typically lose 10-15% of their margin on variations caused by missing or inconsistent scopes, pushing back projects.

Drafting scopes is one of the most time-consuming parts of procurement and has the criminal combination of being easy to mess up and very costly when you do.

The Old Way:

- Scopes take forever to draft and still end up falling short

- Copying scopes from previous projects requires lengthy edits

- Back-and-forth negotiations eat up precious time and energy

The New Way:

- Draft scopes using your own library of pre-configured templates

- Make additions as necessary, and attach comments and learnings

- Complete scopes in minutes with a few clicks

Contracts take too long to get signed

Depending on the trade and supplier, moving a package from recommendation to contract signing can take anywhere from a few days to a few weeks. There are a few reasons this is, namely the recommendation and approval process, contract drafting, and getting sign-off.

Whilst it’s rare, in the worst-case scenarios we’ve heard of subcontractors showing up at the site before having the contract signed — this creates not only financial concerns but legal and safety ones too.

The Old Way:

- Lengthy approval processes with multiple people involved delay contract signing

- Contracts take a while to get drafted, signed, and stored with multiple systems at play

- Some suppliers will still rely on wet signatures

The New Way:

- Our recommendation and approvals workflow notifies the people involved automatically

- Draft contracts from reusable templates, get signed with DocuSign or PDF

- Contracts are drafted, sent, commented on, signed, and stored from one platform

Avoidable errors are common

Whilst it’s not always clear to see how or why, avoidable errors eat up your margin.

Our research puts the figure at between 0.5-1% of your profits. For the UK construction sector as a whole, that’s somewhere in the range of £61,000,000.

The operative word here is avoidable. These are mistakes that are easily made — we’re talking about small errors in contracts, pricing, or documentation that have an incremental, but very real, impact.

If you’d like specific examples, check out our other article, where we’ve identified the top 10 risks/errors in construction procurement.

The Old Way:

- Small oversights or errors on your part create conflicts between you and your vendors

- Margin erodes over time as these errors are repeated project to project

- People make mistakes that machines don’t — outsource the boring stuff

The New Way:

- Controls are baked into your workflows via the central procurement platform

- Simple process errors can’t happen and any lost margin is retained

- Error-prone tasks can be automated and quality checks standardised

Staff satisfaction, recruitment and training

This might be number 12 on our list but is by far the most important.

Construction is an industry that runs on the power of people, relationships, and cooperation. The success of a project might be measured in financials, but for the people working on the project, is it worth it if the work brings misery?

RICS bespoke charity, Lionheart, cites that stress is the biggest health concern for surveyors. Pressure to meet deadlines is exacerbated by tight margins, mounting workloads, and fragile supply chains. Why pile on frustrating, clunky tools?

The Old Way:

- QSs are in demand due to high turnover and fewer people entering the profession

- An ageing workforce is slow to adopt new ways of working that leverage technology

- Stress levels are at an all-time high, employees have a poor work-life balance

The New Way:

- Old procurement workflows are streamlined and simplified into a modern, clean interface

- With admin work reduced, job satisfaction increases

- Happier workers produce better work and attract new talent to your business

The bottom line

These problems aren’t just “pain points” – they’re barriers to profitability, scalability, and success. By addressing them head-on, you can transform procurement from a source of frustration into a competitive advantage.

“Those with best-in-class procurement practices actively contribute to improving their companies’ financial results, with margins that are sometimes five to ten percentage points higher than those of procurement laggards.” - McKinsey, 2023

It’s time to stop patching up problems and start fixing the system. Your team deserves better. Your projects deserve better. And ultimately, your bottom line demands it.

Over the last 5 years, we’ve spent over 20,000 hours solving the biggest problems in construction procurement. ProcurePro is the result of that work — the first of a new category in construction technology, providing an end-to-end procurement solution for construction companies.

Book your Digital Procurement Strategy Workshop

%20(2).png?width=157&height=50&name=McNab_Logo_Landscape-Without-Strapline-Colour(RGB)%20(2).png)